Product Design

Rede D'Or - Meal Production Intelligence

Replaced manual meal counting with automated consolidation, reducing operational time from 120 hours monthly to 15 minutes (99.8%) and eliminating food waste.

Year:

2025

Industry:

Healthcare

Client:

Rede D'Or

Project duration:

3 months

Overview

Hospital Vila Nova Star serves 200+ meals daily. One nutrition professional manually counted every order bed-by-bed, spending 4 hours per cycle on defrosting calculations. This consumed 120 monthly hours, leaving zero capacity for dietary optimization or patient-specific nutrition planning.

MY ROLE

Lead product designer: workflow analysis, interaction design, legacy assessment, Córtex migration strategy.

THE CHALLENGE

Eliminate manual counting while enabling consumption analytics by diet category for evidence-based menu planning. Managed integration constraints by designing within legacy visual patterns initially (faster deployment, user acceptance), then migrating to Córtex for improved usability.

Context

THE LANDSCAPE

Hospital Vila Nova Star operates 107 beds serving 428 daily meals (patients + companions). One professional managed the entire workflow manually: bed-by-bed counting, defrosting calculations, consolidation.

Both failure modes created problems. Excessive defrosting wasted ingredients. Insufficient defrosting denied patients required meals. Neither was acceptable in a recovery-critical context.

KEY CHALLENGES

Manual workflow absorbed 120 monthly hours (equivalent to 15 workdays).

Each meal cycle demanded 4 hours for defrosting calculations.

No consumption data forced guesswork planning rather than trend analysis.

No capacity for menu optimization or individualized planning.

Paper dependency created measurable costs and operational inefficiency.

DESIGN CONSTRAINTS

Integration with Rede D'Or infrastructure required designing within legacy patterns initially. This accelerated deployment and user acceptance before migrating to Córtex for improved usability and system-wide consistency.

THE OPPORTUNITY

Automate production reporting to eliminate manual consolidation, redirecting 120 monthly hours toward strategic patient care. After proving value, migrate to Córtex to improve interface consistency and usability.

The solution

STRATEGIC DECISIONS

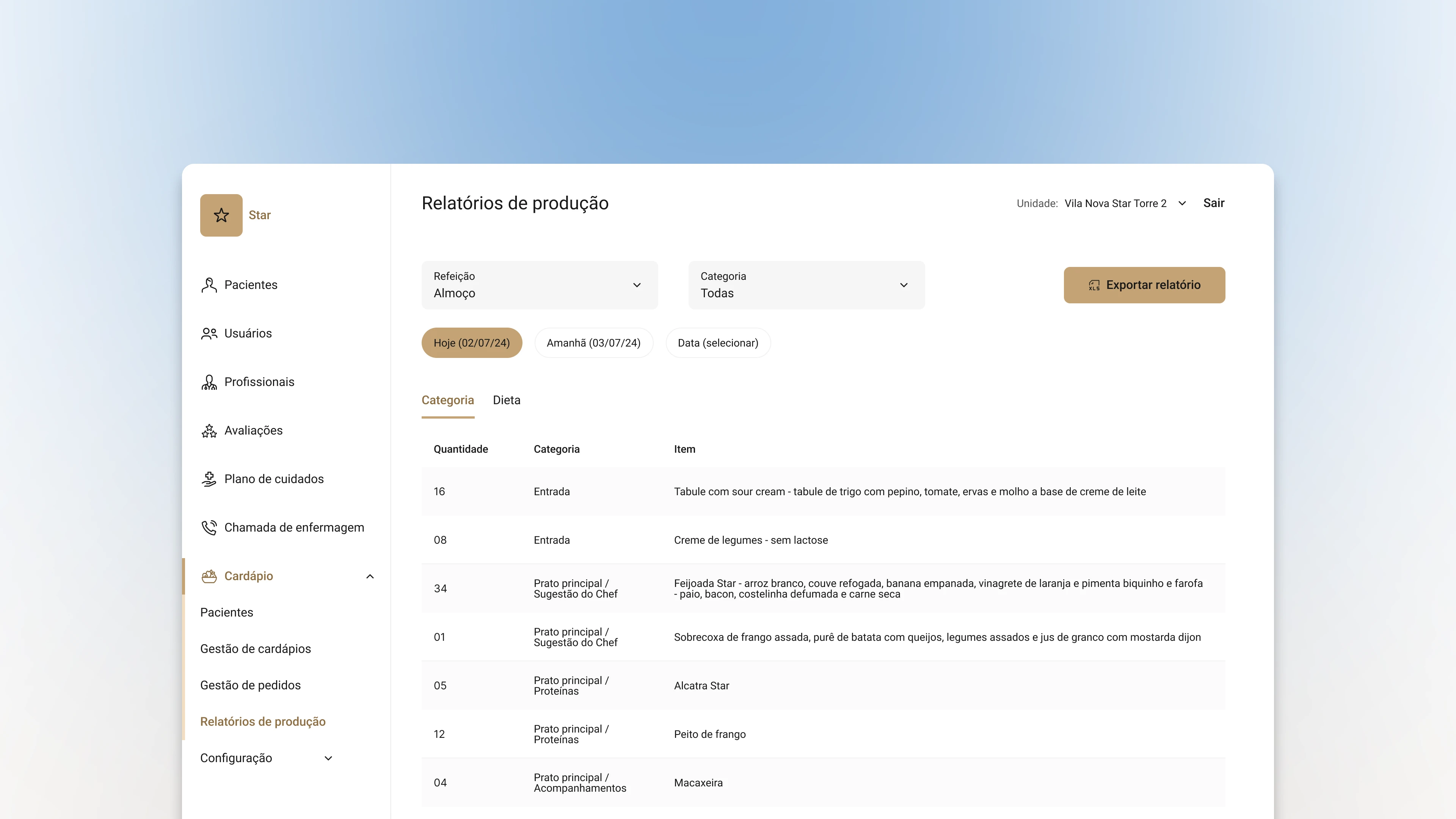

Complete automation, not assistance. Eliminated manual counting entirely. System consolidates orders automatically, requiring zero human calculation or verification.

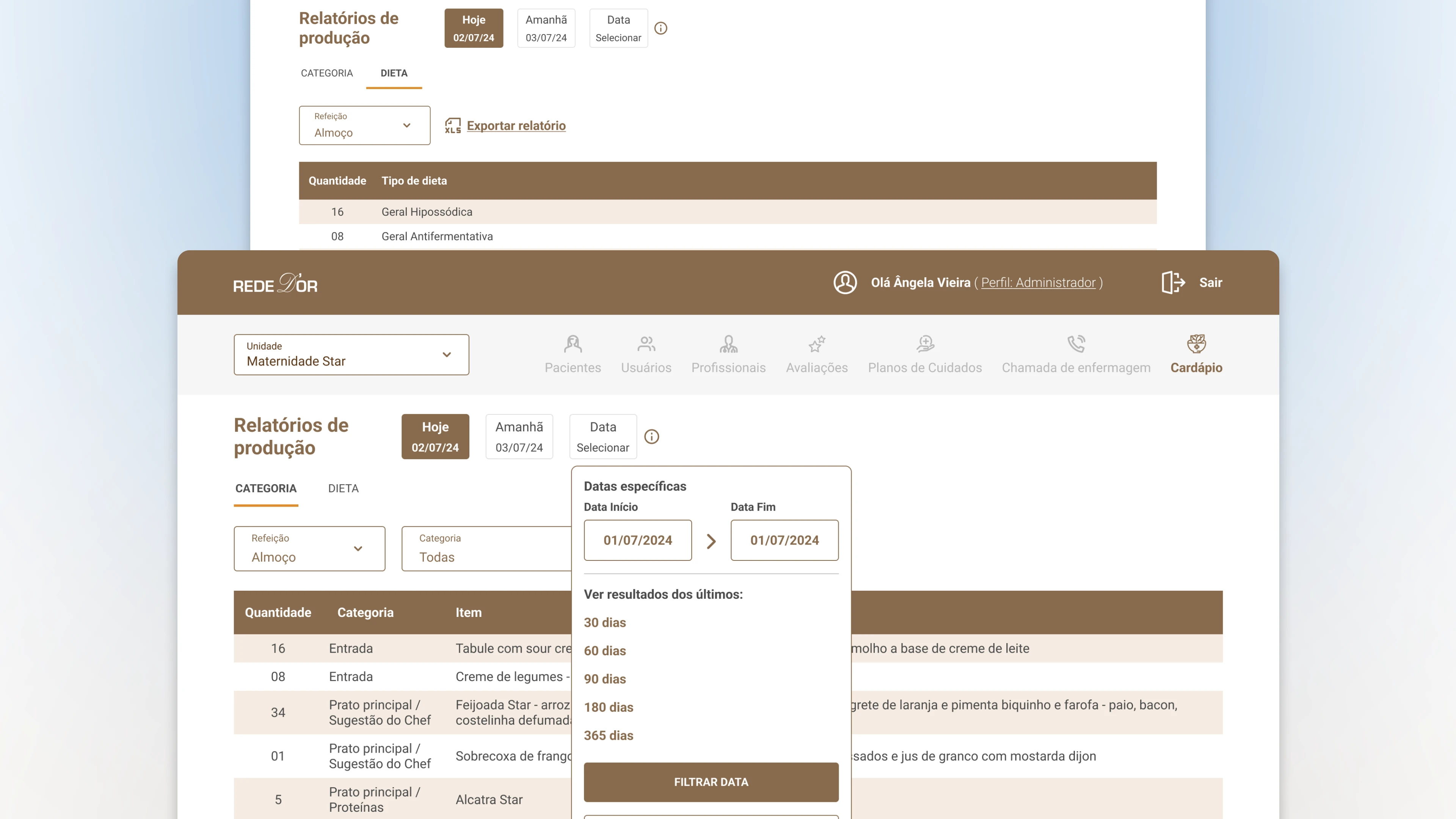

Category-level consumption analytics. Segmented views by diet type reveal which items patients consume most, supporting data-driven menu optimization.

Trend-based planning. Date and category filters reveal consumption patterns, enabling proactive menu adjustments before waste occurs.

Two-phase system migration. Phase 1 used legacy patterns for faster deployment and user acceptance. Phase 2 migrated to Córtex, improving component consistency and reducing maintenance burden without retraining users on established workflows.

CORE FEATURES

Automated meal consolidation eliminating manual counts.

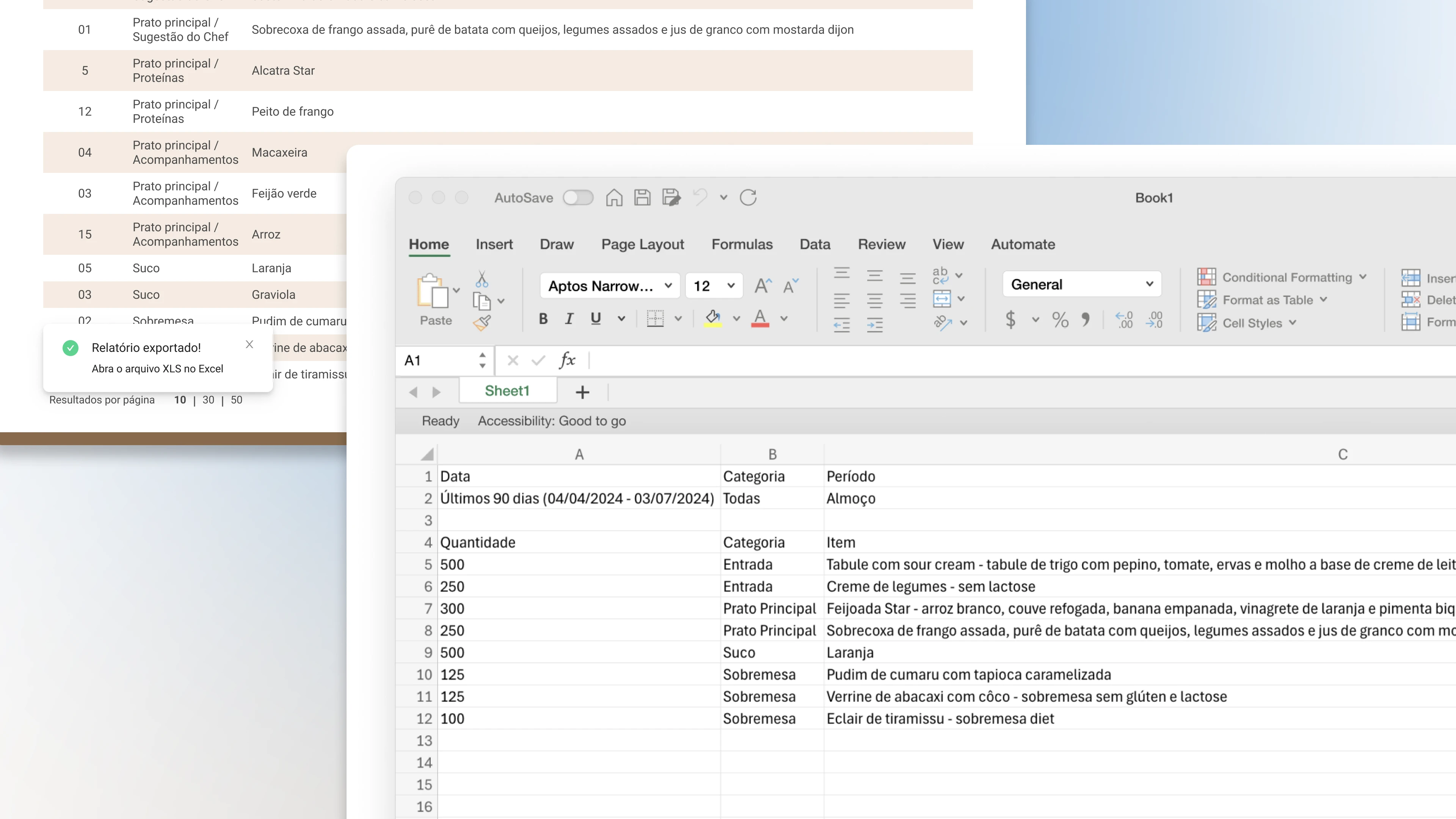

On-demand reports with detailed consumption by category.

Date range filters revealing consumption patterns for menu planning.

Overview dashboard surfacing consumption patterns for menu optimization.

Digital reporting eliminating paper workflows.

DESIGN PRINCIPLES

Operational efficiency. Each action saves time.

Actionable data. Information enables immediate decisions.

Time redistribution. Redirects focus to patient dietary care.

Key Learnings

Automation creates strategic capacity. Primary value: redirecting time from counting toward patient-specific dietary needs, directly improving care quality.

Visibility transforms planning. Filtered views revealed patterns, enabling proactive menu adjustments and reducing waste from low-adoption items.

Healthcare operations demand reliability. Both excess and shortage create problems. System required absolute accuracy as defrosting cannot be reversed.

Phased design system migration reduces risk. Starting with legacy patterns accelerated integration and user acceptance. Córtex migration then improved usability without disrupting workflows. This proved more sustainable than simultaneous implementation in operationally-critical contexts.

Screens after Córtex migration

Expected Outcomes

QUANTITATIVE IMPACT

99.8% reduction in consolidation time, from 120 hours monthly to 15 minutes.

99.7% reduction per meal cycle, from 4 hours to 30 seconds.

83% reduction in paper printing costs.

Elimination of food waste from excessive defrosting.

Elimination of meal shortages.

OPERATIONAL IMPACT

Nutrition professionals can redirect time toward strategic activities: analyzing consumption patterns, optimizing menus, ensuring dietary requirements are met precisely.

BUSINESS IMPACT

Cost reduction via waste elimination and 83% lower printing costs. Resource optimization by redirecting manual labor toward strategic nutrition planning. Scalable solution applicable across Rede D'Or hospitals with in-house kitchens.